Electronic impulse demagnetizers

Thanks to extensive experience in the demagnetization field we are able to provide different demagnetization technologies according to the customer’s specific application. With a careful analysis of the project variables such as: the geometry and dimension of the parts, the type of material, the transfer system and the production process, the productivity and the residual magnetism requirements we formulate proposals that are the most advantageous possible for the customer. We formulate the most advantageous possible proposals for the Customer, evaluating the overall economy of the system, the quality of demagnetization, energy consumption, functionality and ease of use. Thanks to patented technology and on-going improvement over the years, we build electronic impulse demagnetisers that ensure very high performances. In most cases, the electronic demagnetizers realize a minimum residual magnetism, and extremely low energy consumption (on average 150 w), which is as much as 20-30 times lower than the consumption of other demagnetizers. High degree of demagnetization value repeatability and no magnetic retention during the part transfer. Demagnetizers characteristics and performances>

AC tunnel demagnetizers

We furthermore propose demagnetizers with traditional technology that are suitable for other applications. Thanks to the special demagnetization coils constructions, out standing values are guaranteed in terms of residual magnetism, lower energy consumption and limited magnetic retention.

Measurement of the residual magnetism

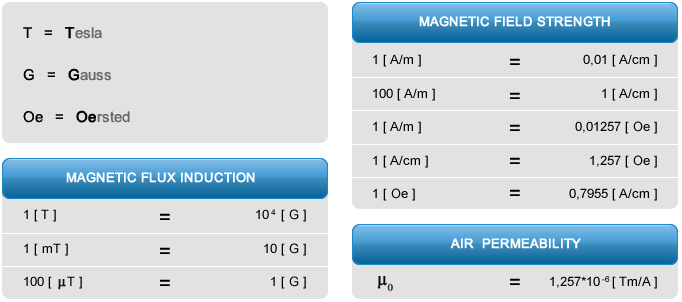

Main unit of measurement and conversion table