|

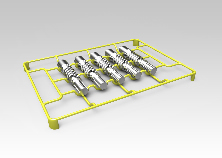

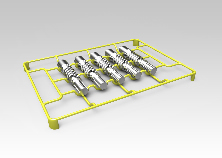

Off line and Manual Demagnetizers for the demagnetization of single parts or parts placed in washing and transport containers. The loading of the pieces to be demagnetized are done manually by the operator in all models. The manual and off line electronic impulse demagnetizers may be:

- With the electronic control unit and coils integrated in a single machine

- With separate electronic control unit and coils

Example of operation:

- The operator positions the part or the container with the parts on the demagnetization coil.

- The op. pushes the demagnetization button: the demagnetization is instantaneous.

- The op. unloads the demagnetized part or the container with parts.

Characteristics and Advantages:

- Simplicity and speed of use

- Compact: very small dimensions

- Minimum energy consumption (< 150 W)

- Easy installation

- Almost zero maintenance

Options:

- Possibility to programm dedicated signals, e.g. for signal exchange with traceability devices

- Possibility to install dedicated lamps for the operator

Technical data required for a quote:

- Part geometry

- Minimum and maximum part dimensions

- Demagnetization of the single part or parts placed in container

- Dimensions of the container (L x W x H)

- Material of the container

- Positioning of the parts inside the container

- The cycle time (parts/hour);

- Working hours/day

- Minimum residual magnetism required

Applications:

|