|

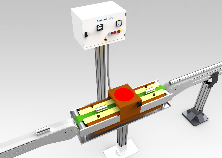

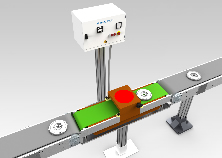

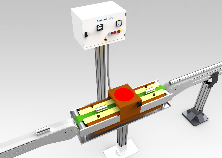

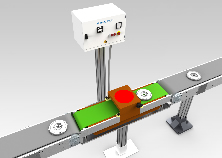

Demagnetizers in line and off line with conveyor belt for the demagnetization of single parts or parts placed inside washing and transport containers. The DU series is subdivided into:

- DU1 and DU2 Models: demagnetizing units with compact conveyor belt consisting of an electronic control cabinet and separately, a conveyor belt with integrated coil.

- DU3, DU4 and DU5 Models: completely integrated demagnetizing units consisting of an electronic control unit and a conveyor belt with coils, in a single machine.

Examples of installation:

- installed in line between two rollers conveyors

- installed in robotised cells with automatic part loading-unloading

- used off lined by the operator, with manual part loading-unloading

Characteristics and Advantages:

- Compact: very small dimensions, according to the parts to be demagnetized

- High productivity

- Minimum energy consumption (< 150 W)

- Easy installation

- Easy interface and I/O exchange with the line

- Almost zero maintenance

Options:

- Manual versions, with manual coil height adjustment

- Automatic versions, with automatic coil height adjustment

- Two-directional conveyor belt motion (weight limits for some models)

- Possibility of planning the dedicated signal exchange with the line

- Possibility of installation of customised control panel

- Waterdrip: machining liquid collection tank

Applications:

Technical data required for a quote:

- Part geometry

- Minimum and maximum part dimensions

- Max weight of the parts

- Demagnetization of the single part or part placed in container

- Dimensions of the container (L x W x H)

- Material of the container

- The cycle time (parts/hour)

- Working hours/day

- Parts transfer system

- Minimum residual magnetism required

|